At one point in achieving success for sustainable transportation, the Swiss maritime expert has successfully delivered and installed the first two -stroke ammonia marine engine, and this is a significant leap to the future of low carbon maritime.

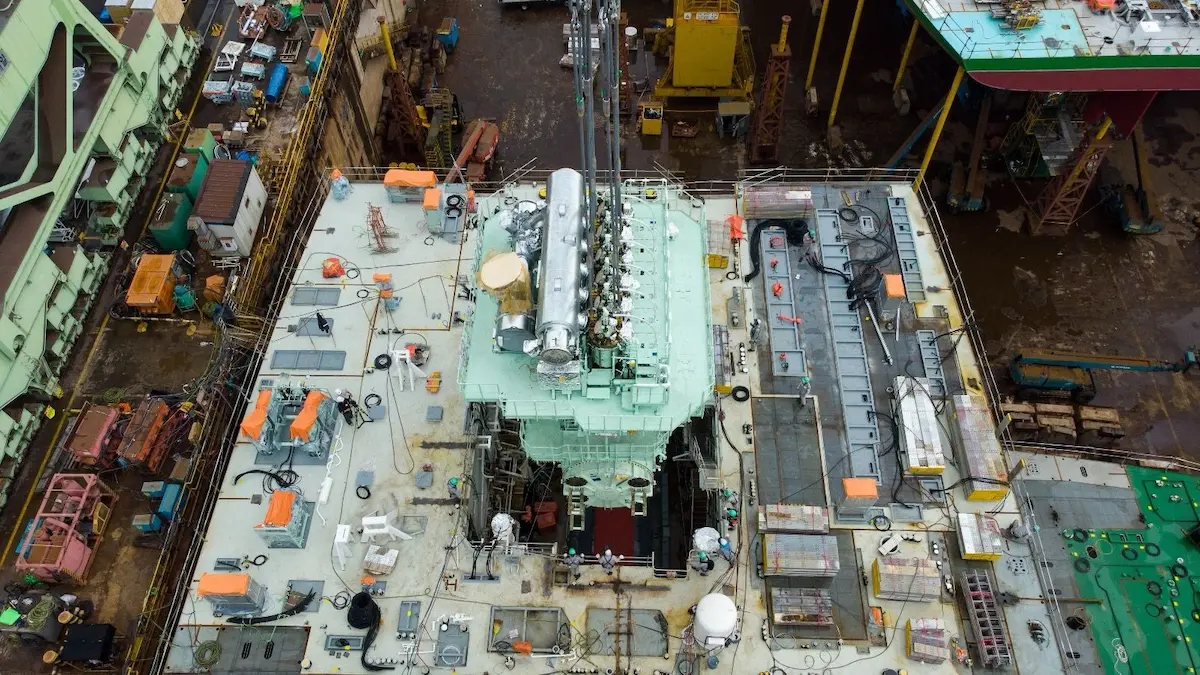

The engine, an X52DF-A 52-Bore, is currently building an LPG/46,000-meter ammonia carrier under construction for Exmar in Dockyard HD Hyundai Mipo in South Korea.

This ship is not just one other ship but that is The first company carrying the world’s ammonia gas To enter commercial services, and X52DF-A is the first in a new generation of zero carbon engines that go to the seas.

First move in ammonia propellers

The latest WingD development turns it into the first engine designer to market a two -stroke ammonia -powered engine.

Made by the HD HYUNDAI (HHI-MD) engine, the engine was heavily tested and tested to match the performance of conventional diesel engines, indicating low greenhouse gas emissions, excellent cargo transportation and high fuel efficiency.

What separates this engine is its high -pressure ammonia injection system, which is only 5 % in full load with a precise dose of the pilot. These combined settings enable it to change between ammonia and diesel modes without being effective or reliable.

Words of Wingd Research and Development Leadership

“With such convincing results, it is clear that ammonia fuel plays an important role in our industry to doVice President of Research and Development in Wingd Sebastian Hansel said.

“Working with comet partners such as ExMar is essential to market this technology. We are proud to be at the top of the clean energy transfer and offers innovative propulsion solutions that the industry needs because it tries to have a more sustainable future,“Hansel added.

A steps to the Decarbonaisation Maritime

Successful installation of the X52DF-A engine is not just a turning point in engineering, but ammonia validity as a suitable marine fuel.

When it comes to renewable sources, ammonia can reduce greenhouse gases by up to 90 % compared to conventional fuels and make it one of the most promising zero carbon options for ocean transportation.

Currently, WingD innovation is increasing, with an initial order book about 30 engines for different types of ships, including gas carriers, bulk and container ships. The second engine is expected to be delivered in the 52 -born Series later this year, and most of the propulsion system is forecast.

Cooperation in the nucleus

Wingd gives firm cooperation between engine manufacturers and ship owners, especially with Exmar and HHI-MD, which is very important for ammonia transportation. This partnership model has guaranteed that the new engine adheres not only technical and functional standards but also safety, reliability and commercial survival.

As the surveillance frameworks evolve and the Decarbonisation goals are firmly firm, the WingD ammonia engine platform provides a real and ready solution for ship owners looking for their fleet.

About the wings

The headquarters in Winterrtor, Switzerland, Wingd (Winterur Gas & Diesel LTD.) has been at the forefront of its roots as Soulzer Diesel in 1893.

Today, the company directs the responsibility of marine deciring through cutting technologies to reduce greenhouse gas emissions, fuel efficiency, hybrid systems and digital optimization.

Through its global service by WingD, the company offers a round -the -clock support cycle with the support of Engineering Excellence and a global service network.